Heat treatment

A true pioneer in the field of metal heat treatment, the THERMILYON group has been promising customized solutions for every metal part, covering a wide range of industrial sectors, for over 60 years.

Ask for a quoteOur heat treatment solutions

Hardening is a mass treatment consisting of heating a part, then cooling it at a certain rate to modify the structure of the steel. As the part leaving the furnace is very hard, it becomes more brittle. Tempering is then applied to reduce brittleness and adjust hardness.

Light alloys generally refer to aluminum-based alloys that require special structural hardening treatment.

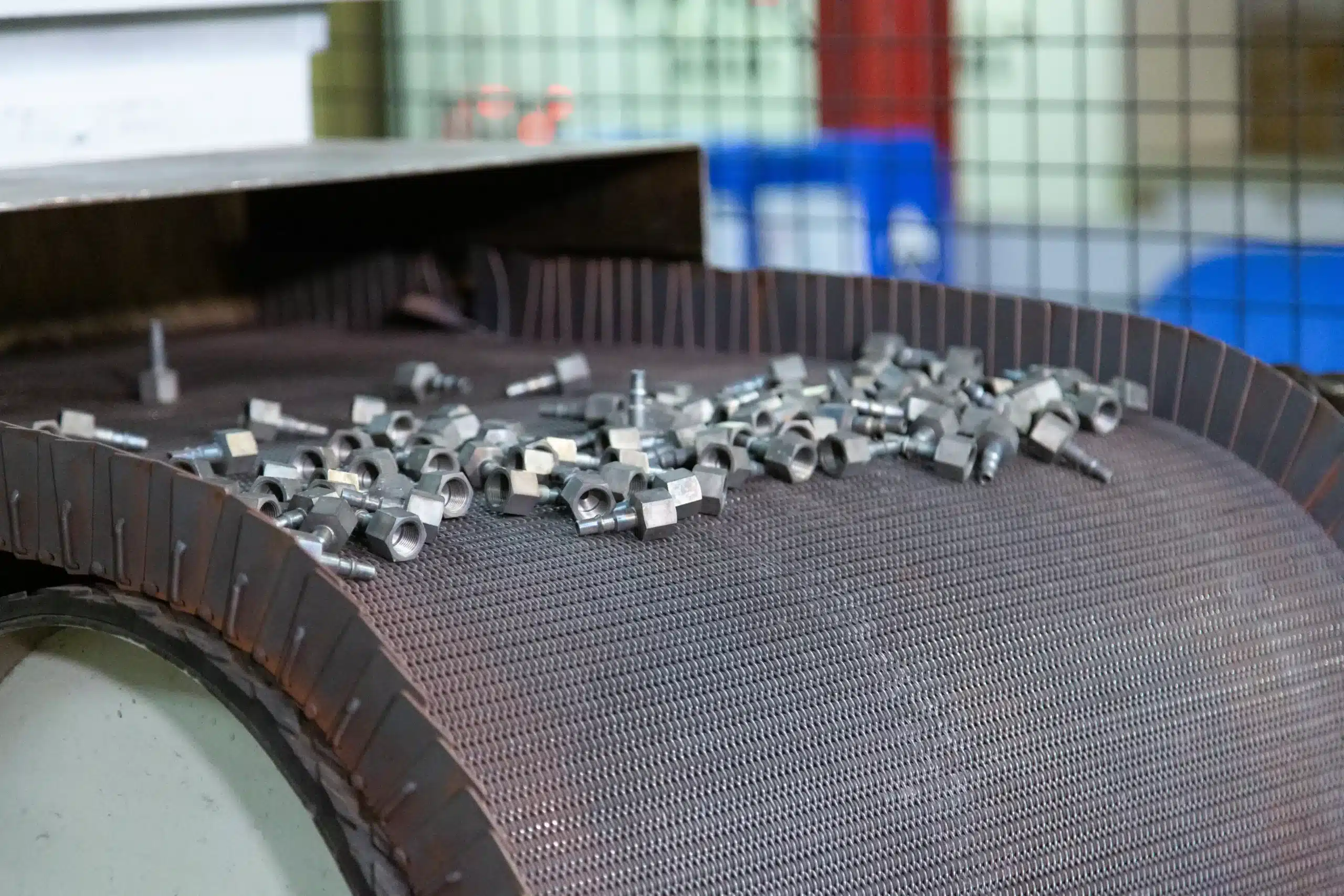

Case-hardening is a treatment that diffuses carbon into the steel's surface layers to achieve very high surface hardness, while retaining good toughness at the core. In carbonitriding, nitrogen is added to the carbon.

Nitriding is the diffusion of nitrogen onto the steel surface, forming nitrides and hardening the surface. Carbon can also be diffused, in this case called nitrocarburizing.

Sulfonitriding is a nitrogen- and sulfur-based treatment. Based on nitriding, sulfur is injected to form iron sulfides and impart tribological properties to the surface. In sulfonitrocarburizing, nitrogen, carbon and sulfur are diffused (sulfur-doped nitrocarburizing).

Stainless steels, commonly known as "inox", require special treatments to maintain their good properties. That's why Groupe ThermiLyon has developed a complete range of products adapted to these steels.

Surface treatments can be carried out to provide additional properties to other heat treatments.

Duplex treatment consists of superimposing a thermochemical treatment such as nitriding or carburizing, and a vacuum coating. The aim is to improve undercoat strength for better coating adhesion. Find out more about our vacuum deposition solutions.

Our certifications

ISO 13485 establishes the criteria for the quality management system of an organization providing medical devices and related services in compliance with customer requirements and applicable regulations.

Read moreEN 9100 certification guarantees the quality management system requirements of the ISO 9001 series, and specifies additional definitions and notes for the aerospace and defense industry.

Read more

The IATF 16949 standard, dedicated to the automotive sector, establishes criteria for quality management processes, encouraging continuous improvement, defect prevention and the reduction of non-conformities and scrap within the automotive supply chain.

Read more

NADCAP is an accreditation program for aerospace and defense subcontractors, designed to ensure the quality and reliability of products and services. This accreditation focuses on the special processes employed in the manufacture, testing and maintenance of components and systems used in these industries. Within the THERMILYON Group, NADCAP applies only to the special heat treatment process.

Read moreThe ISO 9001 standard, widely recognized throughout the world, helps organizations improve their performance by meeting quality management system requirements and demonstrating a commitment to customer satisfaction.

Read moreSee all our certifications

Our FAQs

It's an operation that modifies the internal structure of an alloy to change its properties. In general, there are 3 phases: heating, holding at temperature and slow or rapid cooling (in this case called quenching).

Either to improve mechanical performance such as tensile strength, impact strength, wear, seizure or to soften the metal to make it more malleable (machinability, shaping).

Heat treatment is required when the mechanical performance of the alloys in their natural state needs to be increased. Depending on the type of treatment, heat treatment can be carried out on raw, rough or finished machined parts.

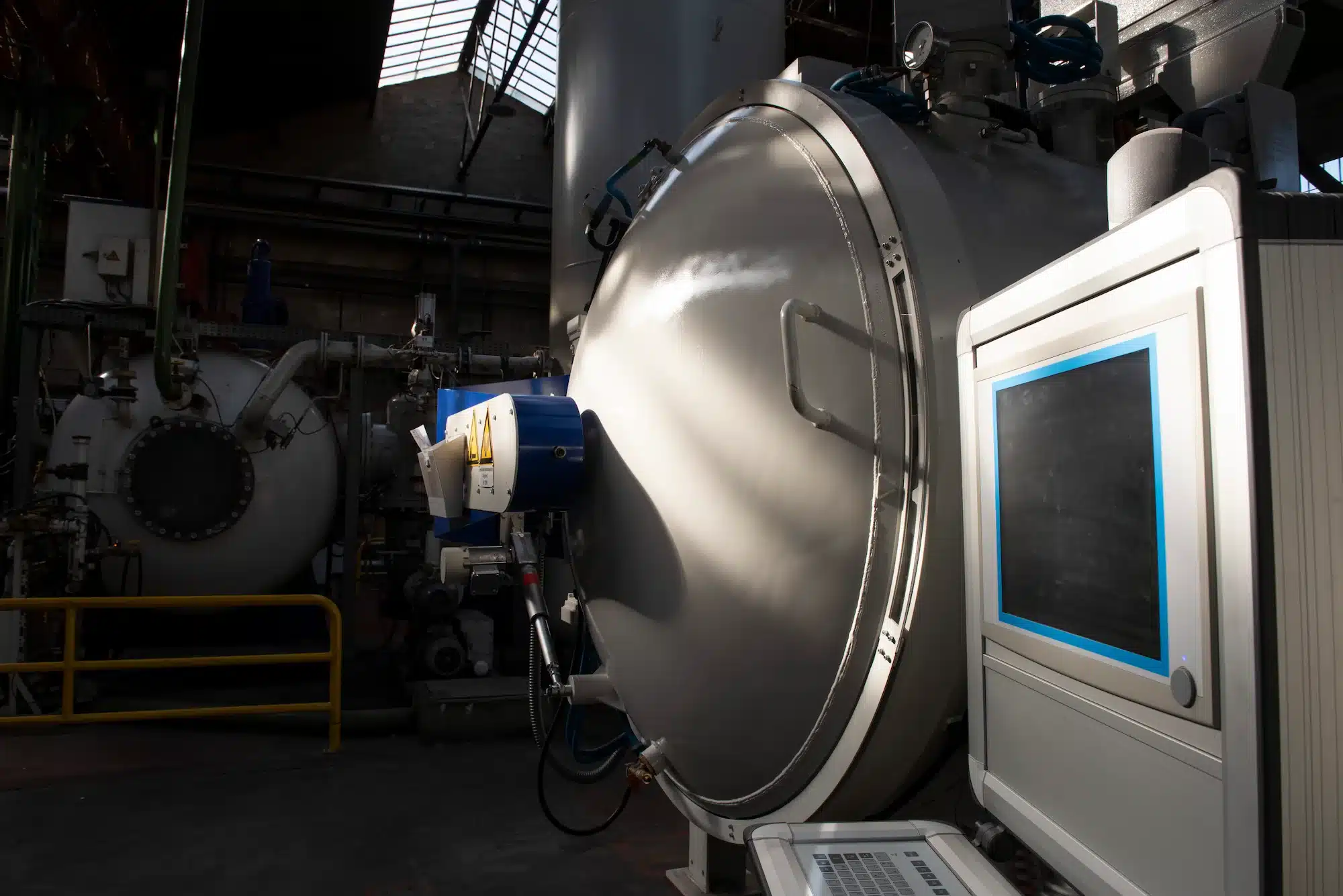

Heat treatment is carried out using furnaces. There are air, atmosphere, vacuum, plasma and induction furnaces.

There are two main types: softening treatments to improve the shaping or machining of parts, modify or improve the metallurgical structure or defragilize certain mechanisms. Hardening treatments in the mass or on the surface to improve the mechanical performance of components.

Heat treatment is one of the only ways to improve the mechanical strength of metals, and therefore their performance. Alloys such as steel, stainless steel, aluminum, titanium and copper all have improved mechanical strength, wear resistance, seizure resistance and corrosion resistance thanks to heat treatment.

To carry out a heat treatment, we first need to take into account the part's use and the mechanical stresses it will have to withstand in its environment. Depending on these factors, the material/treatment pairing is defined.

Do you have a question or a need?

For all your heat treatment projects, our dedicated team is at your service.

Contact usOur latest news

Discover the latest news on heat treatment.