business sectors concerned

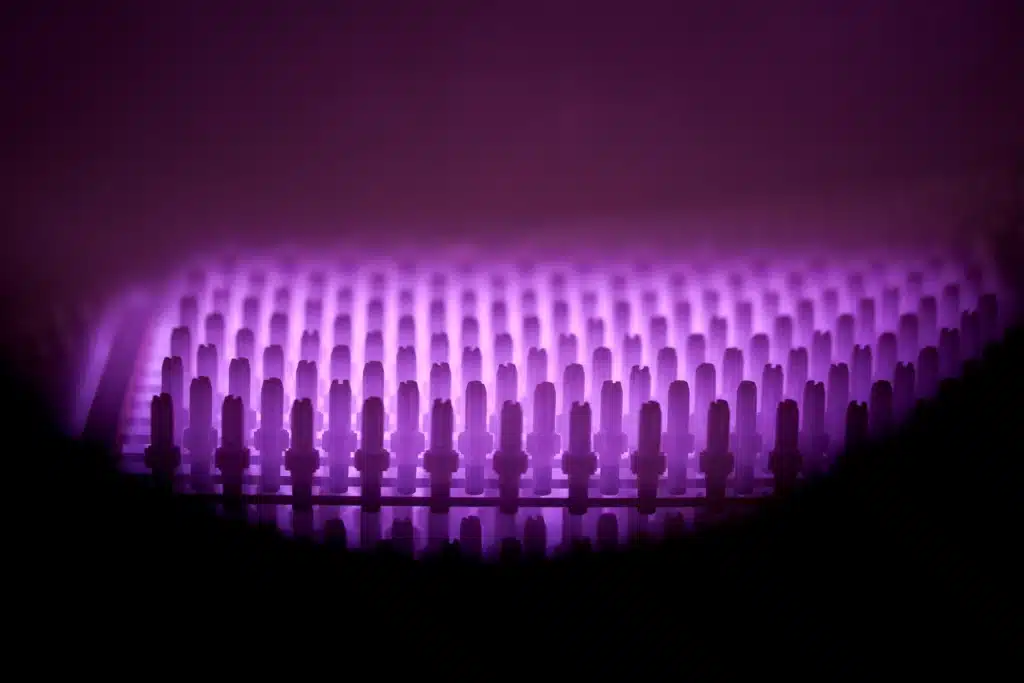

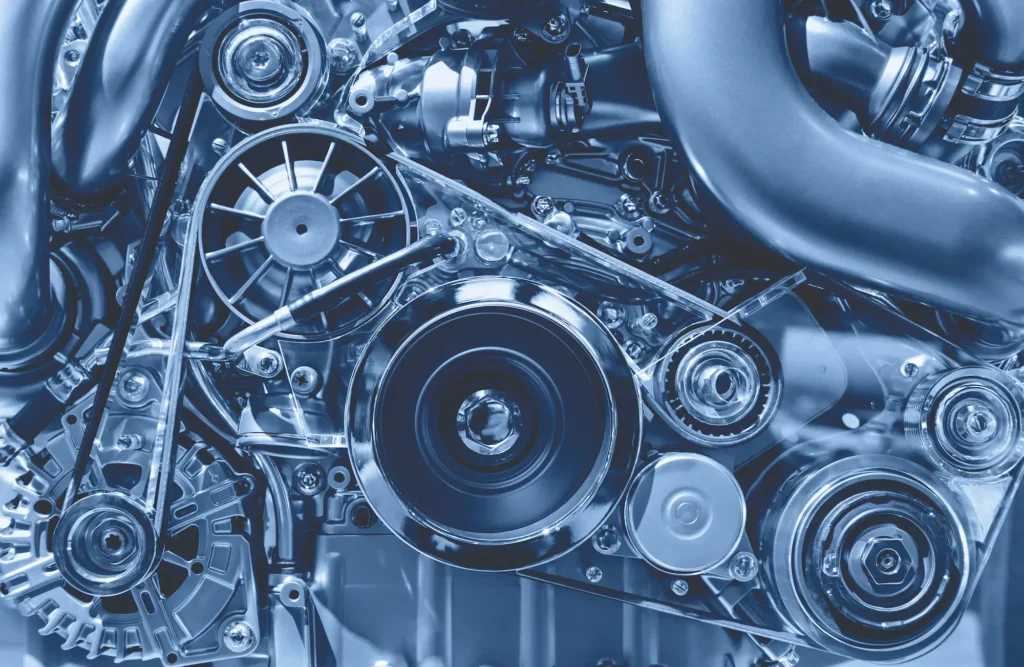

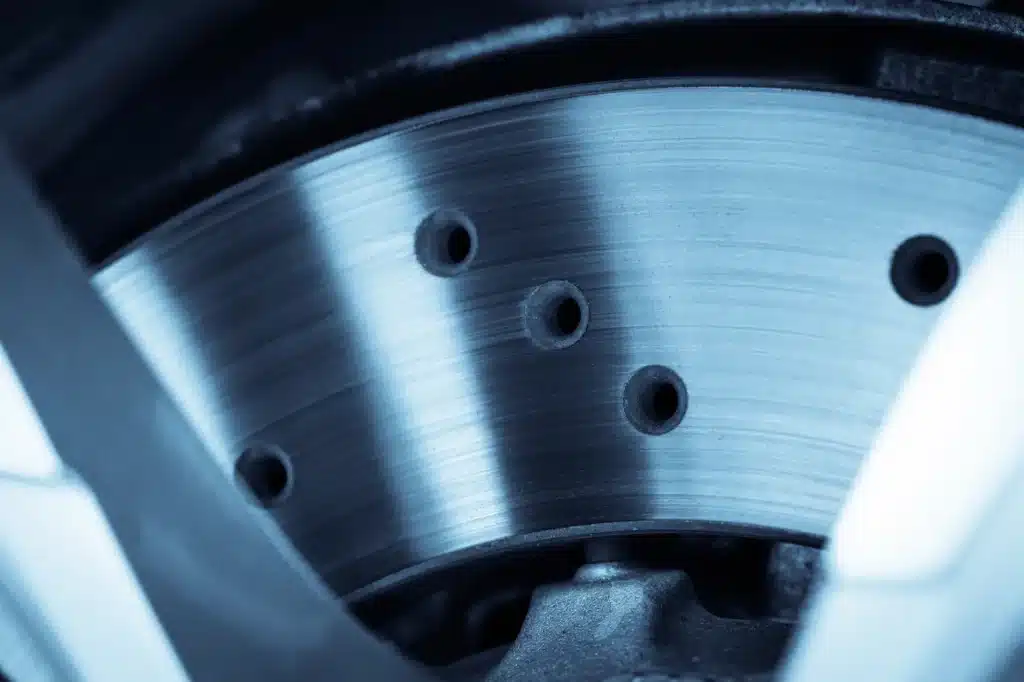

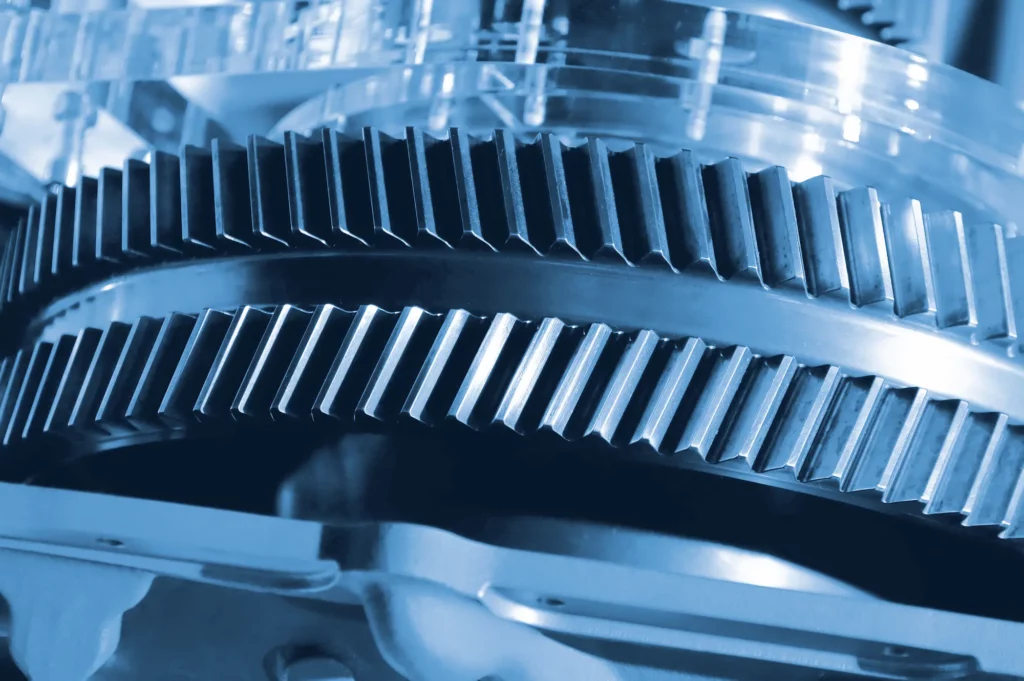

The sulfonitrocarburizing process is ideally suited to parts and tools subject to high wear, abrasion, seizure and fatigue.

Discover our documentation

Our FAQs

Incorporate carbon below the surface of the steel part to improve fatigue and wear resistance on the surface, while maintaining good core mechanical properties.

Low-pressure carburizing uses furnaces with electric heating, very small quantities of carburizing gas and often neutral gas cooling. Traditional carburizing uses furnaces with gas heating, an atmospheric pressure carburizing atmosphere and oil quenching.

Cleanliness and a lower level of deformation enable us to make financial savings by eliminating the need for subsequent washing or sandblasting operations, and by reducing the number of repeat machining operations.

Vacuum furnaces guarantee the absence of air, and therefore oxygen, in the furnace. So there is no oxidation. What's more, the low-pressure carburizing process operates at a very low pressure compared with atmospheric pressure, hence the use of vacuum pumps to reach this pressure level.

Parts requiring a high degree of cleanliness (e.g. holes, bores, finished parts), highly machined parts sensitive to deformation, stainless steel parts, etc.

Our latest news

Discover the latest news on heat treatment and vacuum coatings.