business sectors concerned

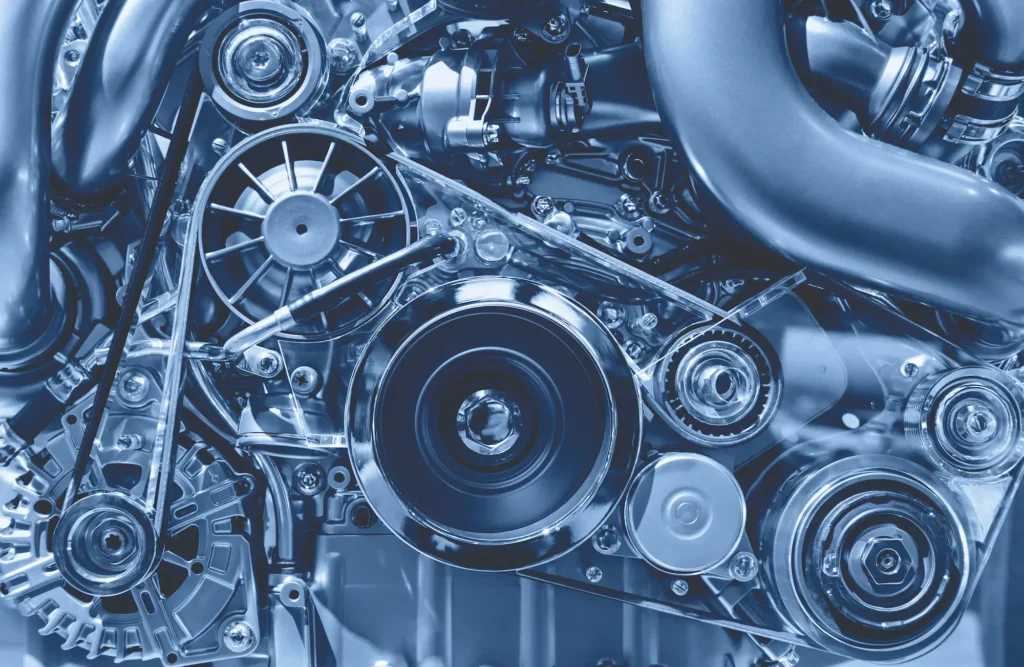

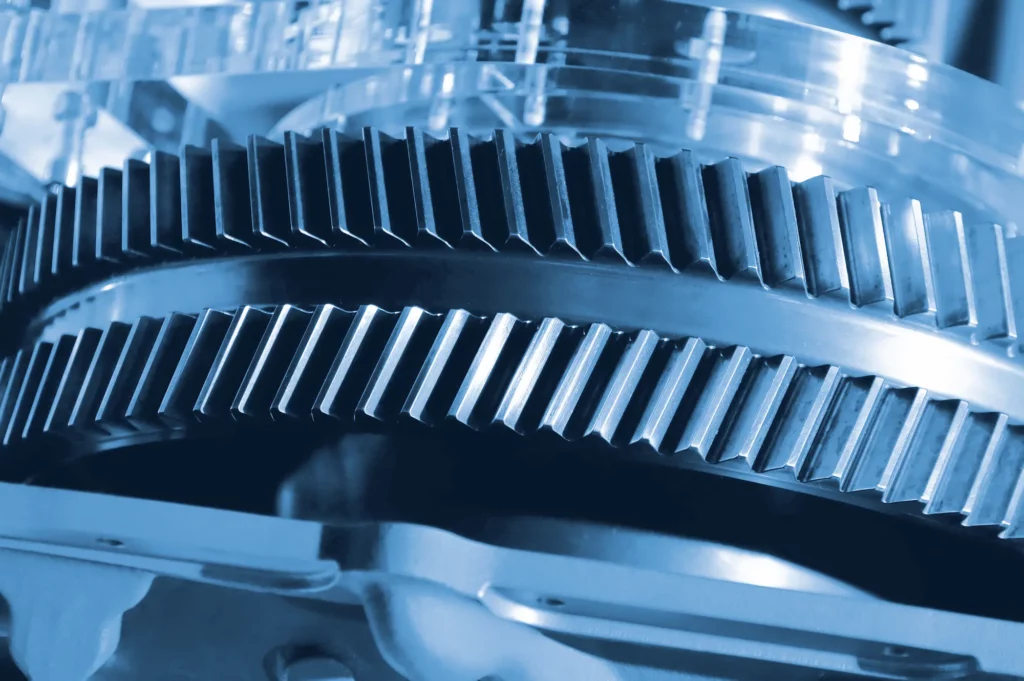

Typical applications: cams, extrusion screws, tooling, slides, gears and all stainless steel parts

Our various documentations

Our FAQs

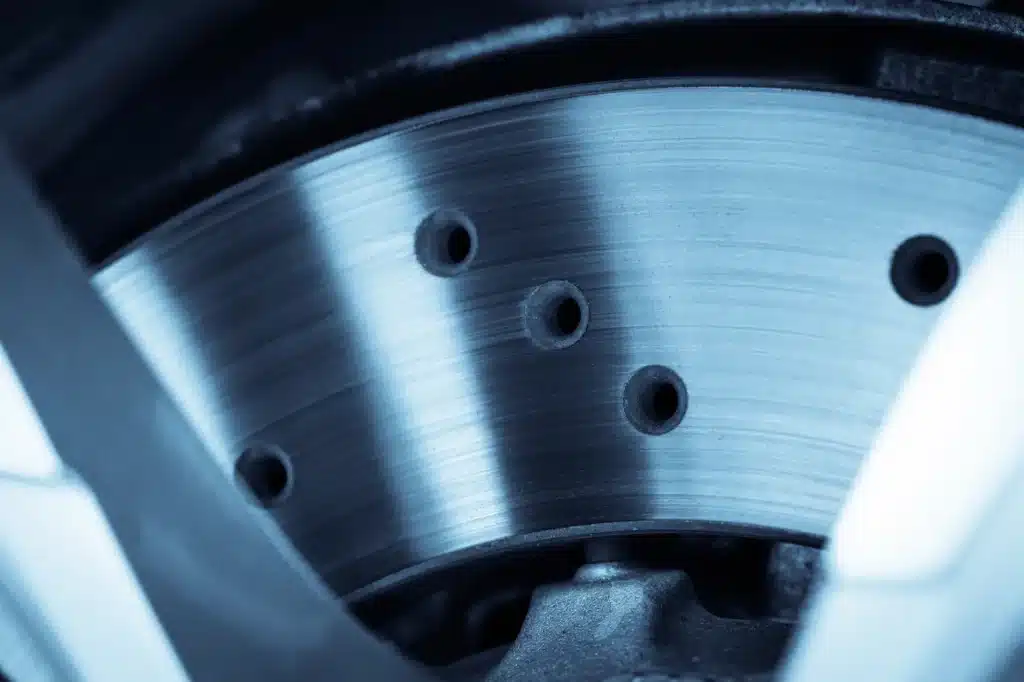

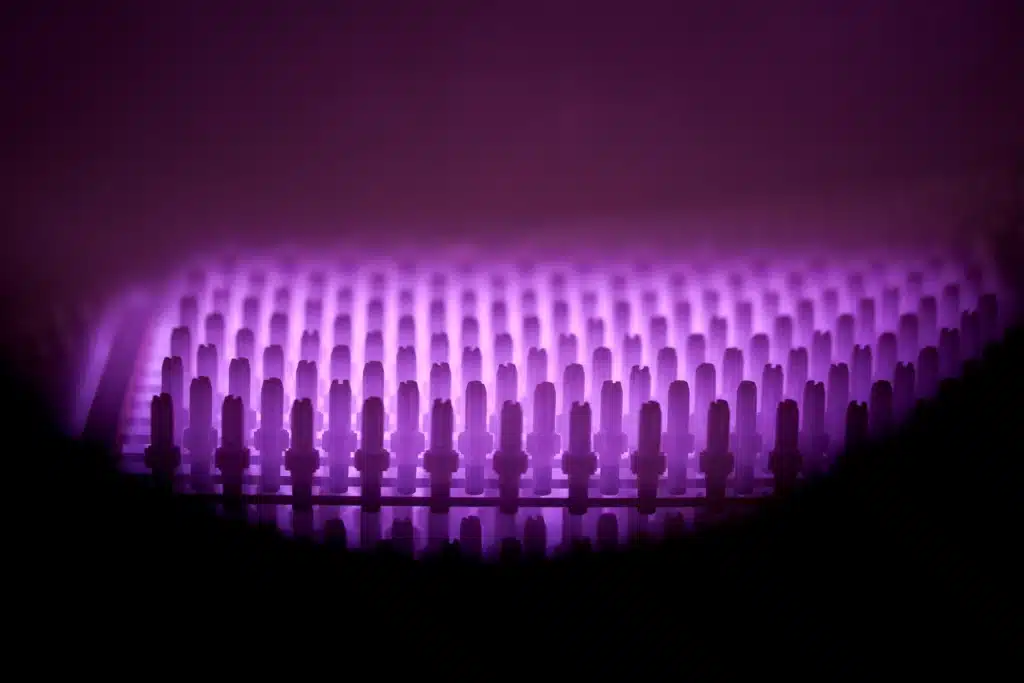

Diffusion of nitrogen on the surface of the part to considerably improve mechanical strength and wear resistance on the surface, while maintaining good core strength. This treatment greatly improves wear resistance, but as the temperature is low (500°C), it causes very little deformation and can be applied to a finished part.

Heat treatment is carried out using furnaces. There are air, atmosphere, vacuum, plasma and induction furnaces.

There are two main types: softening treatments to improve the shaping or machining of parts, modify or improve the metallurgical structure or defragilize certain mechanisms. Hardening treatments in the mass or on the surface to improve the mechanical performance of components.

Type of steel, desired steel characteristics (hardness), quantity of parts per shipment and per year, part drawings and specifications. If possible, the operating mode of the part and its final use.

Do you have a question or a need?

Our dedicated team can handle any ion nitriding project.

Contact usOur latest news

Discover Thermilyon Group news and our best articles on heat treatment.