Thermi-Lyon

THERMI-LYON is the world's first contract heat treatment facility. More than 60 years after its creation, this site has become the group's technological showcase.

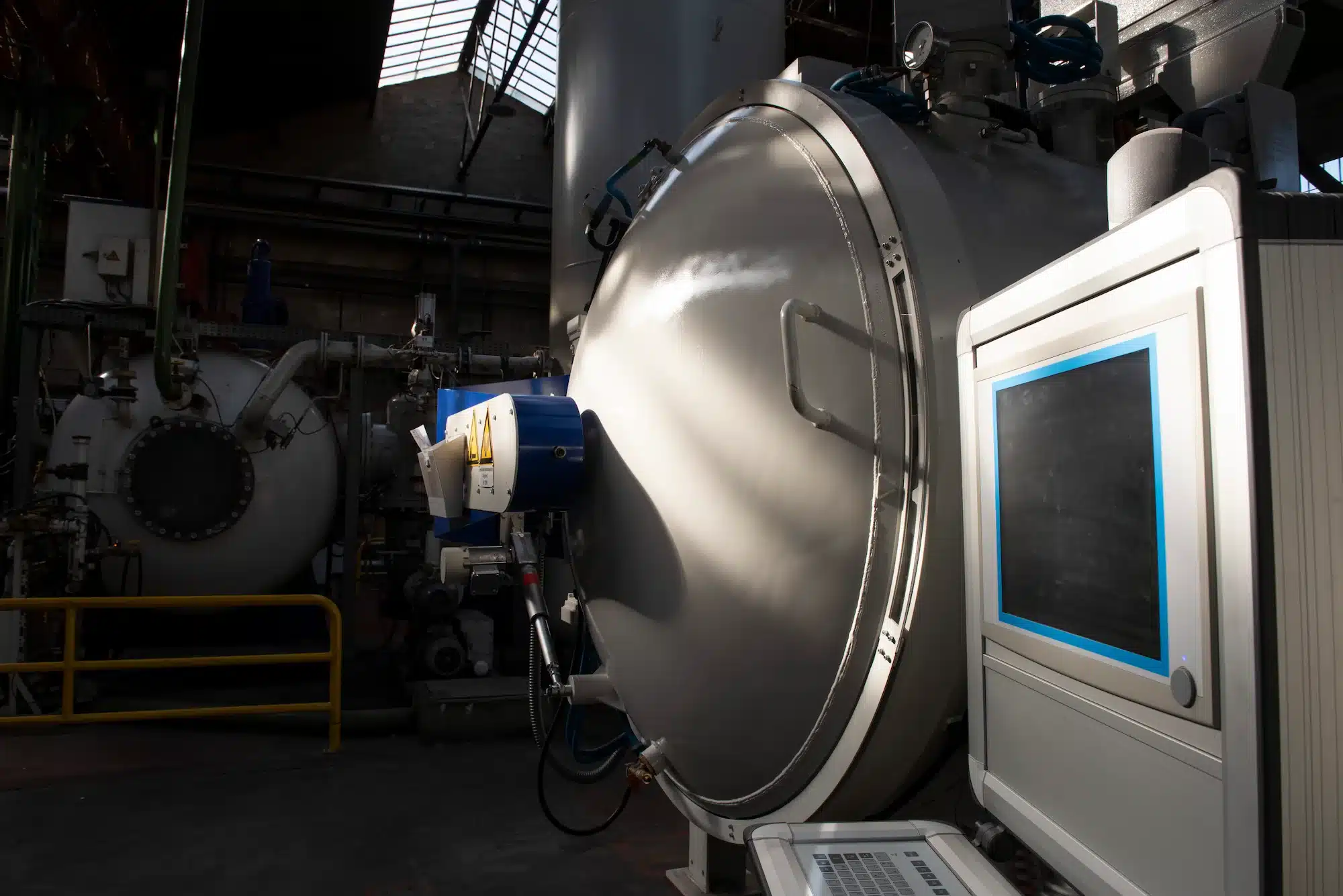

Request a quoteTHERMI-LYON, a true technological showcase

Historically the group's first site, THERMI-LYON was created in 1960 to meet the needs of the Rhône-Alpine mechanical engineering industry.

Its high level of investment in human resources and technology has enabled it to extend its reach nationwide and internationally.

THERMI-LYON has played a major role in the development and industrialization of new heat treatment processes, and has won several MIDEST and A3TS innovation awards.

New processes have been deployed to improve the wear and galling resistance of stainless steels without compromising corrosion resistance: THERMI-SP®.

This powerful multi-treatment unit meets a wide range of customer requirements.

All equipment is linked by a supervision network, enabling continuous data acquisition and remote interrogation.

Address: 13 avenue du château de Gerland 69007 Lyon

Discover our solutions

Site contacts

our thermi-lyon certifications

ISO 13485 establishes the criteria for the quality management system of an organization providing medical devices and related services in compliance with customer requirements and applicable regulations.

Read more

EN 9100 certification guarantees the quality management system requirements of the ISO 9001 series, and specifies additional definitions and notes for the aerospace and defense industry.

Read more

NADCAP is an accreditation program for aerospace and defense subcontractors, designed to ensure the quality and reliability of products and services. This accreditation focuses on the special processes employed in the manufacture, testing and maintenance of components and systems used in these industries. Within the THERMILYON Group, NADCAP applies only to the special heat treatment process.

Read more

The ISO 9001 standard, widely recognized throughout the world, helps organizations improve their performance by meeting quality management system requirements and demonstrating a commitment to customer satisfaction.

Read moreOur latest news

Discover the latest news on heat treatment and vacuum deposition.

Do you have a question or a need?

Let's talk about your heat treatment and vacuum deposition projects and needs.

Contact us