France's leading group in heat treatment and vacuum deposition

Recognized expertise in heat treatment and custom vacuum deposition since 1960.

Ask for a quoteOur certifications

ISO 13485 establishes the criteria for the quality management system of an organization providing medical devices and related services in compliance with customer requirements and applicable regulations.

Read moreEN 9100 certification guarantees the quality management system requirements of the ISO 9001 series, and specifies additional definitions and notes for the aerospace and defense industry.

Read more

The IATF 16949 standard, dedicated to the automotive sector, establishes criteria for quality management processes, encouraging continuous improvement, defect prevention and the reduction of non-conformities and scrap within the automotive supply chain.

Read more

NADCAP is an accreditation program for aerospace and defense subcontractors, designed to ensure the quality and reliability of products and services. This accreditation focuses on the special processes employed in the manufacture, testing and maintenance of components and systems used in these industries. Within the THERMILYON Group, NADCAP applies only to the special heat treatment process.

Read moreThe ISO 9001 standard, widely recognized throughout the world, helps organizations improve their performance by meeting quality management system requirements and demonstrating a commitment to customer satisfaction.

Read moreSee all our certifications

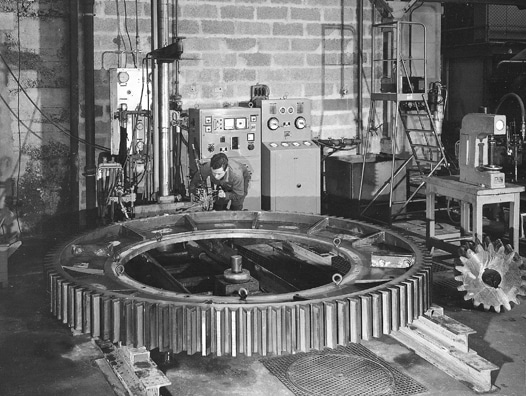

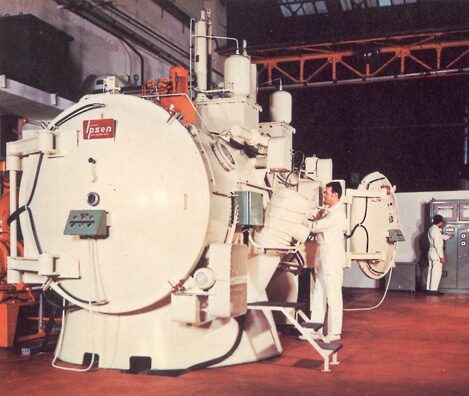

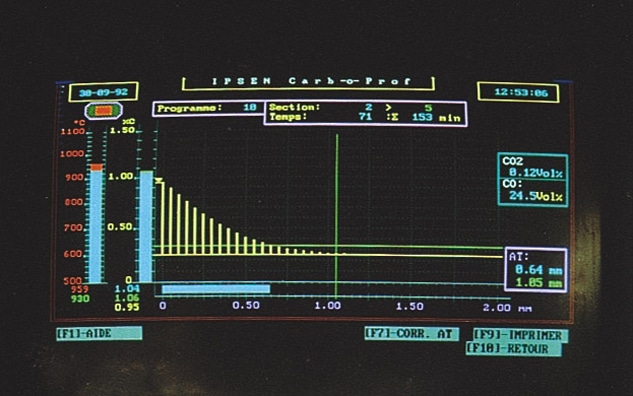

THE THERMILYON GROUP IN PICTURES

Our locations

- 405 Rue de la Précision 74970 MARIGNIER

- +33450345408

- 143 Avenue Benoît Fourneyron 42160 ANDRéZIEUX-BOUTHéON

- +33477555230

- 59 Route de Frouzins 31120 ROQUES

- +33562873410

- 455 Grande Rue 01100 MARTIGNAT

- +33474811001

- 7 Boulevard Paul Langevin 38600 FONTAINE

- +33476278240

- 60740 SAINT-MAXIMIN

- +33344647590

- 32 Strada Griviței DEVA

- +40354409752

- 13 Avenue du Château de Gerland 69007 LYON

- +33478616622

- 174 Rue des Rosses 74970 MARIGNIER

- +33450346980

Meet the thermilyon team

Our latest news

Find out more about Groupe ThermiLyon.