business sectors concerned

Insofar as this solution strengthens stainless steel parts overall, many industrial sectors can derive significant benefit from it. First of all, as mentioned above, the food industry is one of the main sectors concerned. For example, in yoghurt production and packaging plants, components filling individual containers are in constant contact with the product as it will be consumed. It therefore seems essential to prevent these components from flaking off, leaving metal particles inside the yoghurt ingested by consumers.

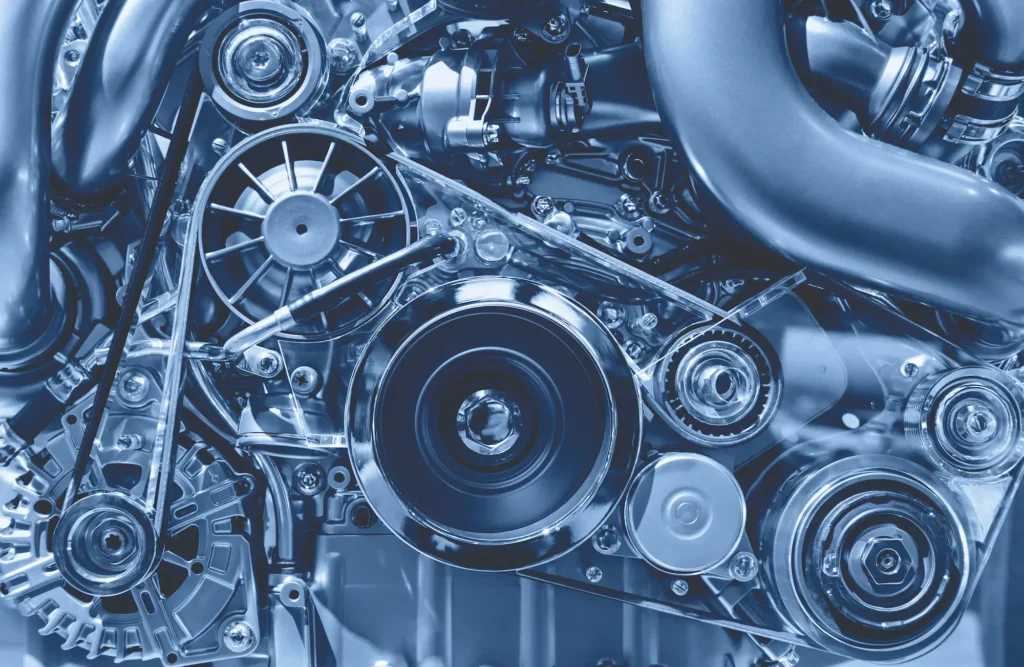

The automotive sector also benefits from this technology, particularly when it comes to treating fuel injectors. As this liquid is highly corrosive, it is essential to treat these parts so that they last as long as possible. Similarly, certain components in the turbos found on some engines remain prone to seizure, as they perform mechanical actions at high temperatures. Thermi®-SP treatment ensures that these parts last even longer.

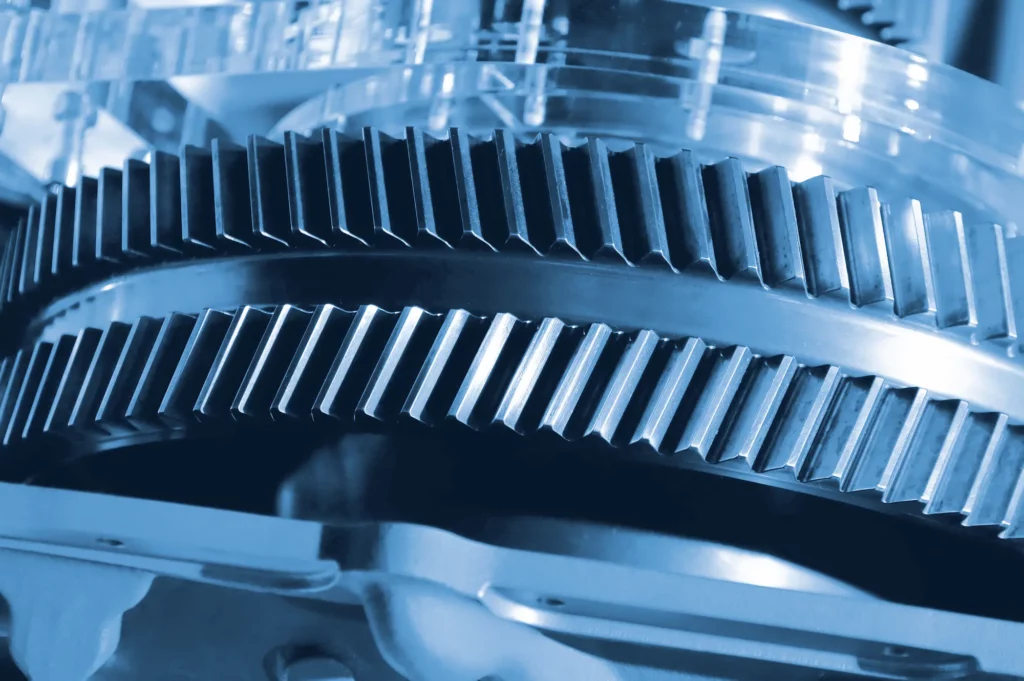

As a result, all industries using or manufacturing stainless steel mechanical parts seem to be concerned by this treatment. On the tooling side, stainless steel screws, nuts and lockwashers are often prone to seizing and wear out quickly, which Thermi-SP can help to slow down, as the structural changes it brings about in the parts help to maintain torque for longer.

Our various documentations

Non-destructive testing of parts treated with Thermi®-SP

Our FAQs

Vacuum deposition is a surface treatment used to deposit a material or alloy on a mechanical part.

The use of vacuum technology ensures a perfectly clean, non-polluting process.

It is not subject to REACH legislation.

This process greatly increases resistance to wear, abrasion, friction and corrosion. As a result, component life is greatly extended.

Standard thicknesses are of the order of 3µm and deposition is carried out on finished parts.

PVD is physical vapor deposition. The element to be deposited is obtained by evaporation or sputtering via a physical process. PACVD is plasma-assisted chemical vapor deposition. The element to be deposited is obtained from chemical reactions. Plasma enables this chemical reaction to take place at lower temperatures.

Vacuum deposits are classified into several categories: anti-wear, friction, decorative and biocompatibility. The applications are therefore very varied: automotive components, aerospace, tooling, cutting tools, medical devices, decorative parts...

The deposition method depends above all on the nature of the coating to be deposited and the substrate.

If the substrate cannot be heated to high temperature, the deposition must be carried out using low-temperature technology.

If the coating to be deposited consists of a solid element (metal or graphite target), a physical process such as PVD is used. If the coating consists of a gas or liquid, a chemical process such as CVD or PACVD is used.

Incorporate carbon below the surface of the steel part to improve fatigue and wear resistance on the surface, while maintaining good core mechanical properties.

Our latest news

Learn more about heat treatment and vacuum deposition in our latest articles.