Thermi-Bugey

THERMI-BUGEY makes its expertise available to plastic injection molders, toolmakers and precision mechanics.

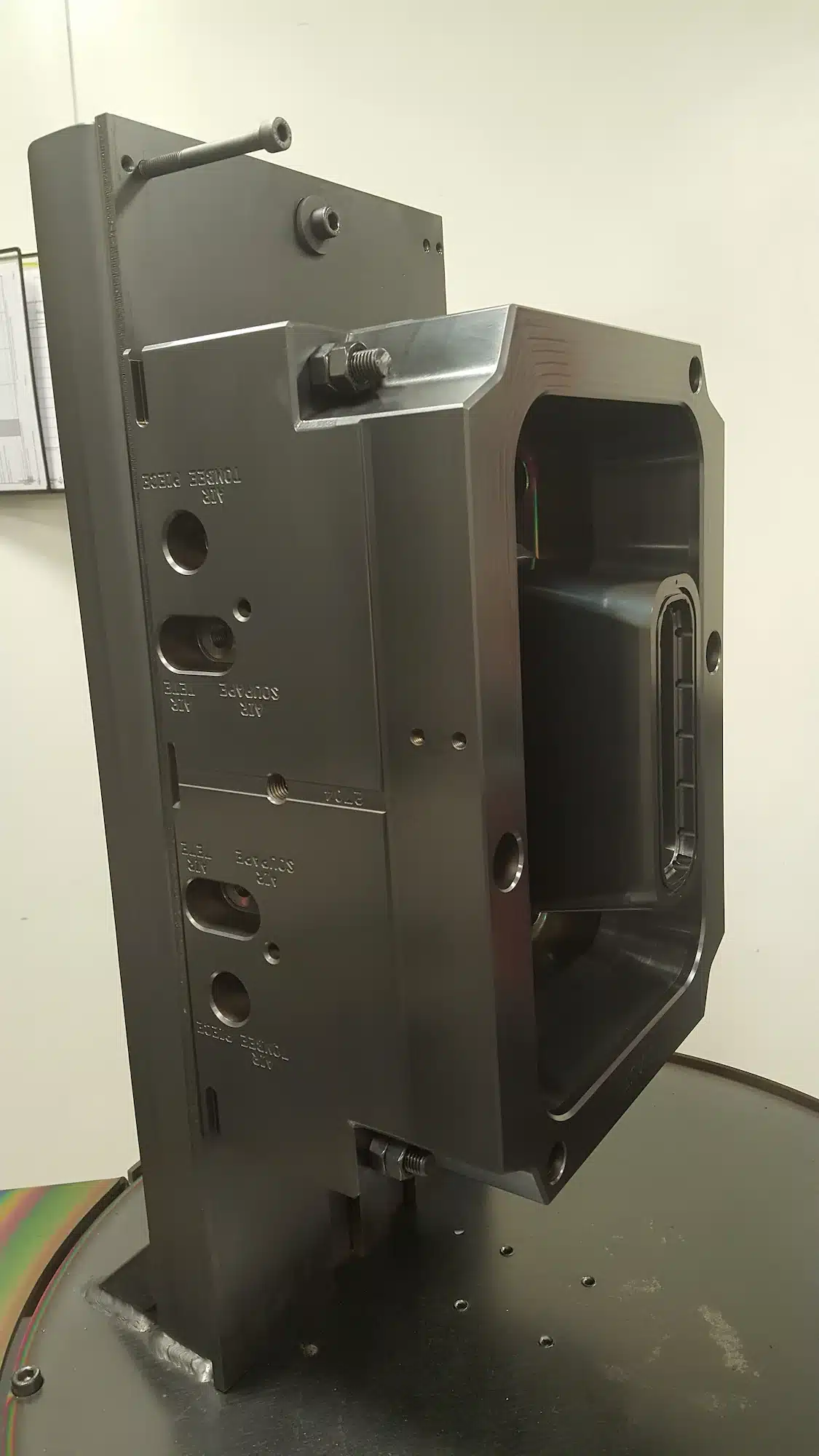

Request a quoteTHERMI-BUGEY, a partner for molding mechanics

Located near Oyonnax, in the heart of Plastics Valley, THERMI-BUGEY was created in 1987 to meet the industrial requirements of moldmakers, toolmakers and precision mechanics .

The quality, reliability and speed of our services are ensured by a competent, available and motivated technical team, and by high-tech equipment.

THERMI-BUGEY has all the technologies required for the mechanical engineering market: vacuum treatment, nitriding, PVD and DLC coatings. Bring together all heat treatment solutions from a single source, with vacuum treatment, low-pressure nitriding and vacuum deposition technologies (synergy with THERMI-PLATIN).

All equipment is linked by a supervision network, enabling continuous data acquisition and remote interrogation.

For local customers in the Oyonnax area, we have our own shuttle service to handle the transport ourselves and relieve our customers of the administrative burden.

Address: 455 Grande Rue 01100 Martignat

Discover our solutions

Site contacts

Our thermi-bugey certifications

ISO 13485 establishes the criteria for the quality management system of an organization providing medical devices and related services in compliance with customer requirements and applicable regulations.

Read moreThe ISO 9001 standard, widely recognized throughout the world, helps organizations improve their performance by meeting quality management system requirements and demonstrating a commitment to customer satisfaction.

Read moreSee all our certifications

Our latest news

Find out more about the Thermilyon Group.

Do you have a question or a need?

Our dedicated team will advise you on the treatments and coatings best suited to your needs.

Contact us