THERMI-LOIRE

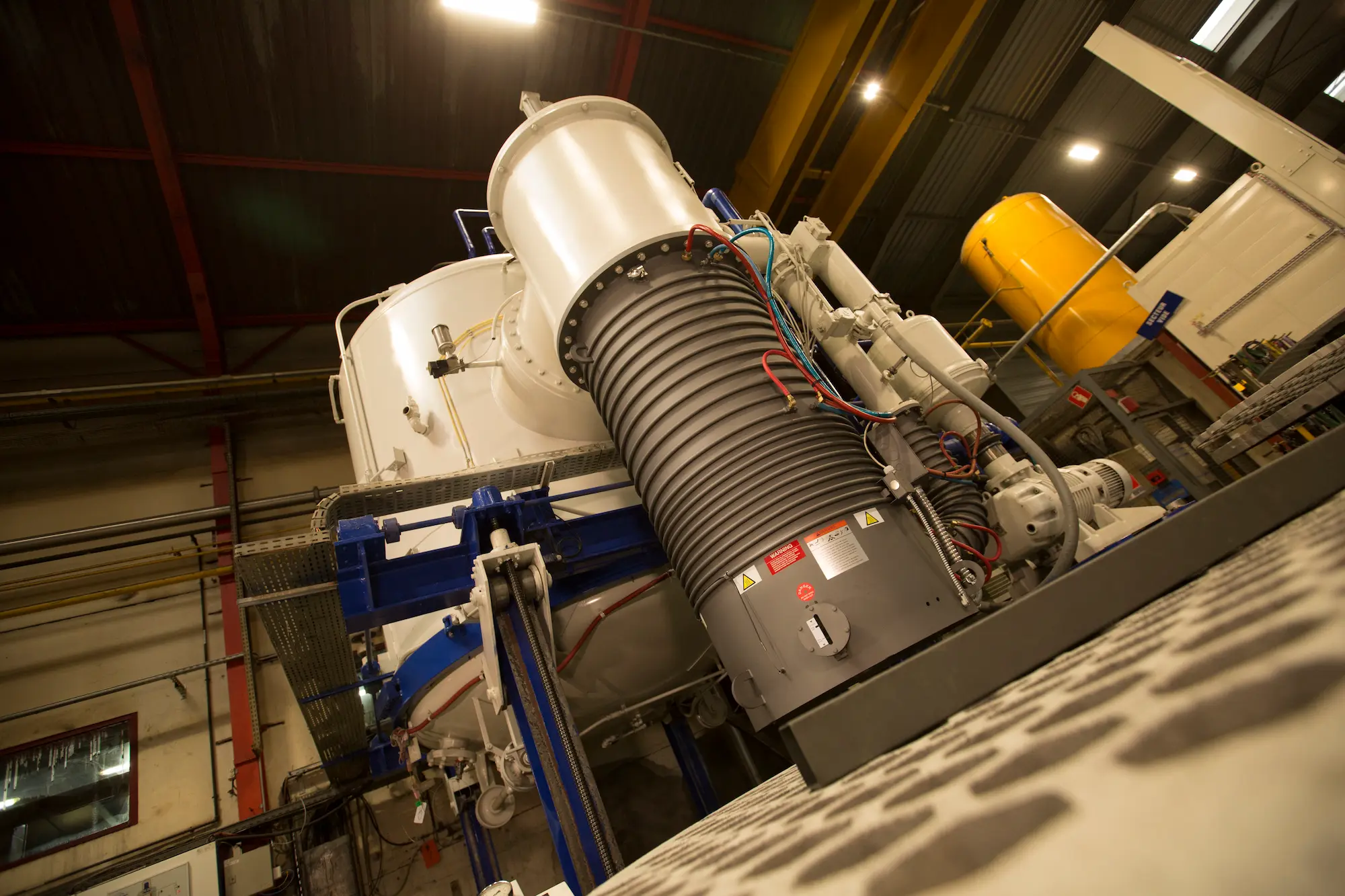

THERMI-LOIRE specializes in the processing of large parts, particularly for the aeronautical industry.

Request a quotethermi-loire, Specialist in large parts

THERMI-LOIRE has been basedin the Stéphano region since 1977, and is a flagship company of the ThermiLyon group.

Located in Andrézieux-Bouthéon, this company specializes in the heat treatment of metals. The site benefits from a strategic position in the heart of the Loire, integrating industrial excellence and technological innovation in all its activities to meet the needs of local industries: forges, gear manufacturers, toolmakers, mechanics...

THERMI-LOIRE specializes in the treatment of large parts, particularly for theaeronautics and automotive industries.

Address: 143 Avenue Benoit Fourneyron 42160 ANDREZIEUX BOUTHEON

Discover our solutions

Site contacts

Our certifications

EN 9100 certification guarantees the quality management system requirements of the ISO 9001 series, and specifies additional definitions and notes for the aerospace and defense industry.

Read more

The IATF 16949 standard, dedicated to the automotive sector, establishes criteria for quality management processes, encouraging continuous improvement, defect prevention and the reduction of non-conformities and scrap within the automotive supply chain.

Read more

NADCAP is an accreditation program for aerospace and defense subcontractors, designed to ensure the quality and reliability of products and services. This accreditation focuses on the special processes employed in the manufacture, testing and maintenance of components and systems used in these industries. Within the THERMILYON Group, NADCAP applies only to the special heat treatment process.

Read moreThe ISO 9001 standard, widely recognized throughout the world, helps organizations improve their performance by meeting quality management system requirements and demonstrating a commitment to customer satisfaction.

Read moreOur latest news

News from the Thermilyon Group and the heat treatment industry.

Do you have a question or a need?

For all your projects, even large ones, our dedicated teams are at your service.

Contact us