Thermi-Platin

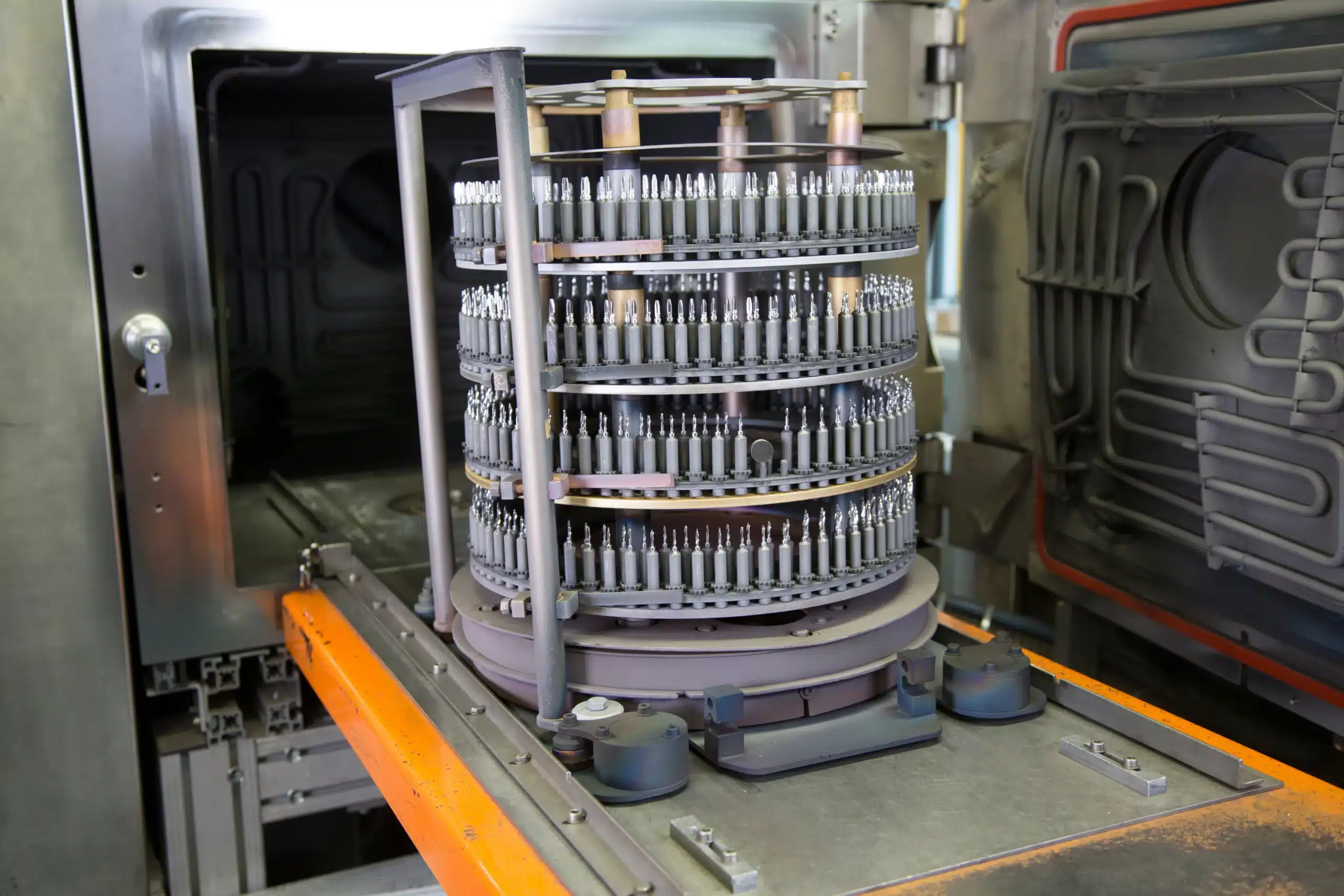

THERMI-PLATIN has made vacuum deposition technologies its specialty, with the aim of providing a complementary solution to heat treatment.

Request a quoteThe vacuum deposition specialist

Founded in 1996 in the heart of the bar-turning industry in the Arve Valley, THERMI-PLATiN' complements heat treatment with vacuum coatings.

A wide range of PVD and DLC coatings covers all applications for tooling, medical devices and wear parts.

THERMI-PLATiN''s ultra-high-performance anti-wear coatings provide tool manufacturers and users with productivity gains to help you remain competitive in your industry.

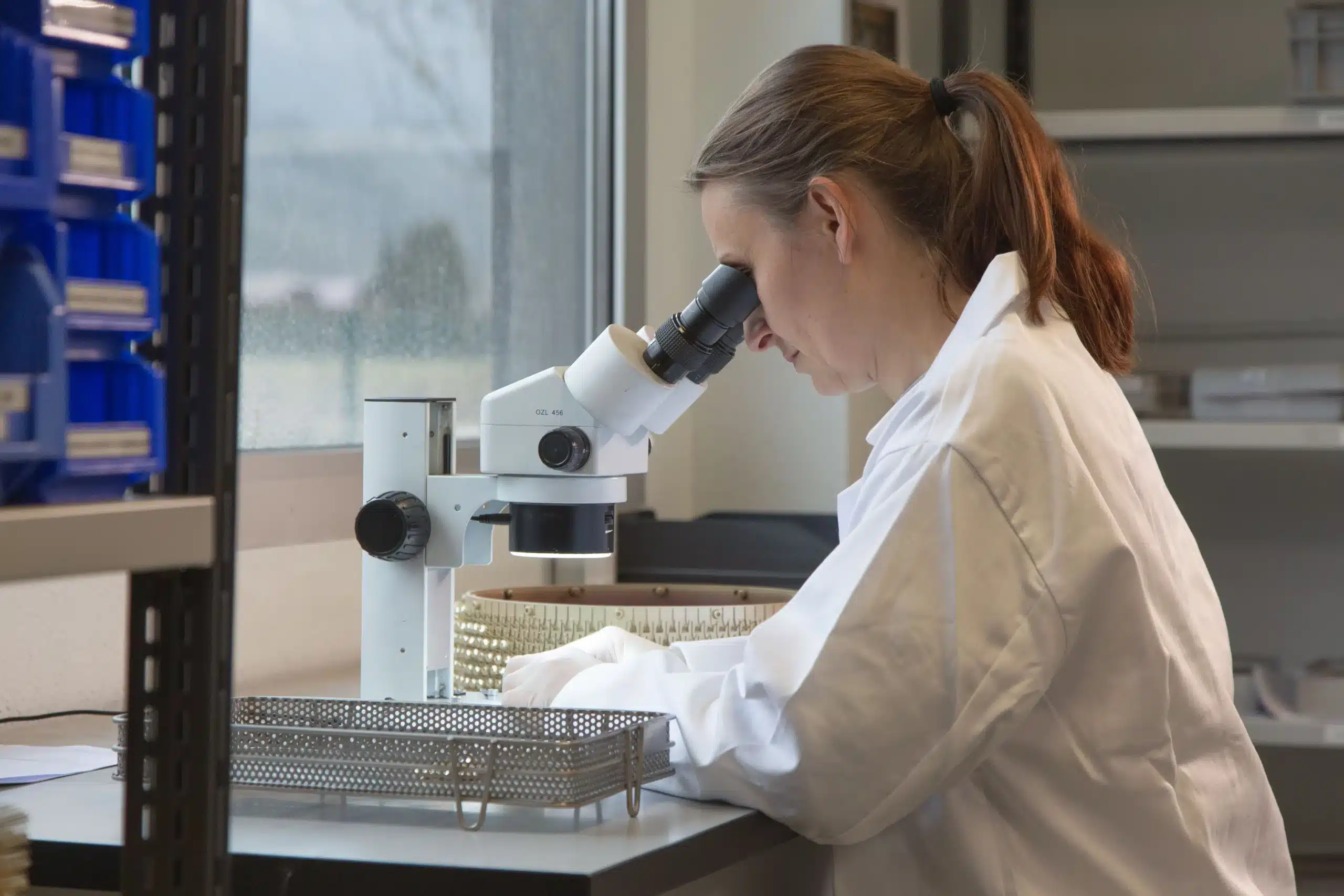

The THERMI-PLATIN site also offers solutions tailored to the medical sector with certified biocompatible coatings: PLATiN® MEDI BETA - PLATiN® MEDI ZrN - PLATiN® MEDI WC-C and THERMI-DLC.

THERMI-PLATIN also masters specific tribological coatings based on DLC carbon: wear parts, mold elements requiring a good coefficient of friction.

Recently, a new technology has been put into operation to produce PREMIUM layers in coating only or in DUPLEX (nitriding + PVD coating in the same enclosure). Equipment to prepare tool edges and improve surface finish for better chip evacuation is also operational.

Address: 174 rue des rosses Marignier

Site contacts

Our certifications

ISO 13485 establishes the criteria for the quality management system of an organization providing medical devices and related services in compliance with customer requirements and applicable regulations.

Read moreThe ISO 9001 standard, widely recognized throughout the world, helps organizations improve their performance by meeting quality management system requirements and demonstrating a commitment to customer satisfaction.

Read moreOur latest news

Discover the latest news from Thermi-Platin and vacuum deposition

Do you have a question or a need?

Our dedicated team will advise you on the coatings best suited to your needs.

Contact us