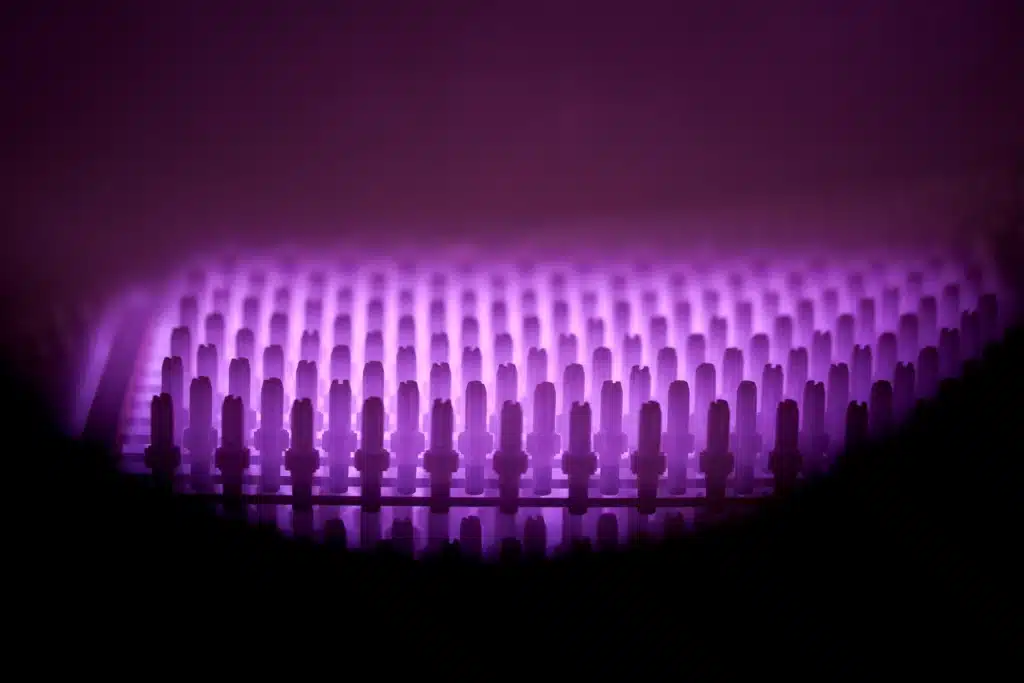

The best-known thermochemical nitrogen diffusion treatment is nitriding. By promoting the formation of nitrides on the surface of metal parts, this process considerably enhances their resistance to wear and fatigue. This type of method offers numerous advantages and is suitable for the vast majority of steels, although nitriding is not the only means available for improving metal performance using nitrogen.

Nitrogen diffusion for better protection of metal parts

The diffusion of a chemical element such as nitrogen into a metal part serves primarily to solidify it. In practice, inserting nitrogen into the material's crystalline structure deforms the lattice, causing compressive stresses to build up on the surface of the material, making it significantly stronger. In other words, incorporating a large quantity of nitrogen into the metal structure distorts the lattice to induce compressive stresses, thereby considerably reducing the risk of crack propagation and breakage. This not only enhances parts' resistance to wear and tear, but also to thermal fatigue, and improves their overall mechanical performance.

3 advantages of thermochemical nitrogen diffusion treatment

Nitrogen diffusion thermochemical treatments modify the structure of metal parts to make them more efficient, more resistant to wear and thermal fatigue. The best-known of these processes is nitriding, which consists in producing nitrides on the surface of materials to make them harder.

Improved wear resistance

Diffusing nitrogen on the surface of a metal part really helps to improve its hardness: after a treatment such as nitriding, this value can rise to 1000 HV, whereas in its natural state, steel hardness is between 200 and 300 HV. In detail, this process is based on the formation of nitrides. These elements are formed precisely by the presence of nitrogen and additives, and prove to be particularly hard, considerably enhancing the wear resistance of the parts. They also guarantee greater mechanical resistance over the long term. This treatment applies not only to steels, but also to stainless steel and titanium.

Better resistance to thermal fatigue

Some naturally corrosion-resistant materials, such as austenitic stainless steels, can be damaged by the formation of nitrides. Thermi Lyon has therefore developed a formula to retain only the advantages of a nitrogen diffusion treatment without nitriding (without nitride formation): Thermi-SP. Thermi-SP. In particular, this treatment enables stainless steels to be treated with the same chemical element, giving them excellent mechanical resistance to fatigue, seizure and wear, without affecting their natural ability to resist corrosion. Depending on the objective, various thermochemical nitrogen diffusion treatments such as nitriding or Thermi-SP can be particularly useful for enhancing the resistance of parts to wear, corrosion, thermal fatigue and high temperatures. Choosing the right solution therefore involves determining whether or not the final material can benefit from nitride formation.

One of the most serious avenues for the development of nitrogen diffusion treatments concerns aluminum. This material remains much softer than steel, and its alumina-protected surface makes diffusion treatments very difficult. This treatment is very promising, but is still at the R&D stage. The challenge would be to raise the basic hardness of aluminum from 80 HV to 200HV to over 1,000 HV at the surface.

Nitrogen diffusion thermochemical treatments transform the metal's structure. Integrating this chemical element into the crystal lattice of parts significantly enhances their resistance to wear, thermal fatigue and corrosion. There are several methods for achieving this, including nitriding and Thermi-SP, developed by Thermi Lyon.