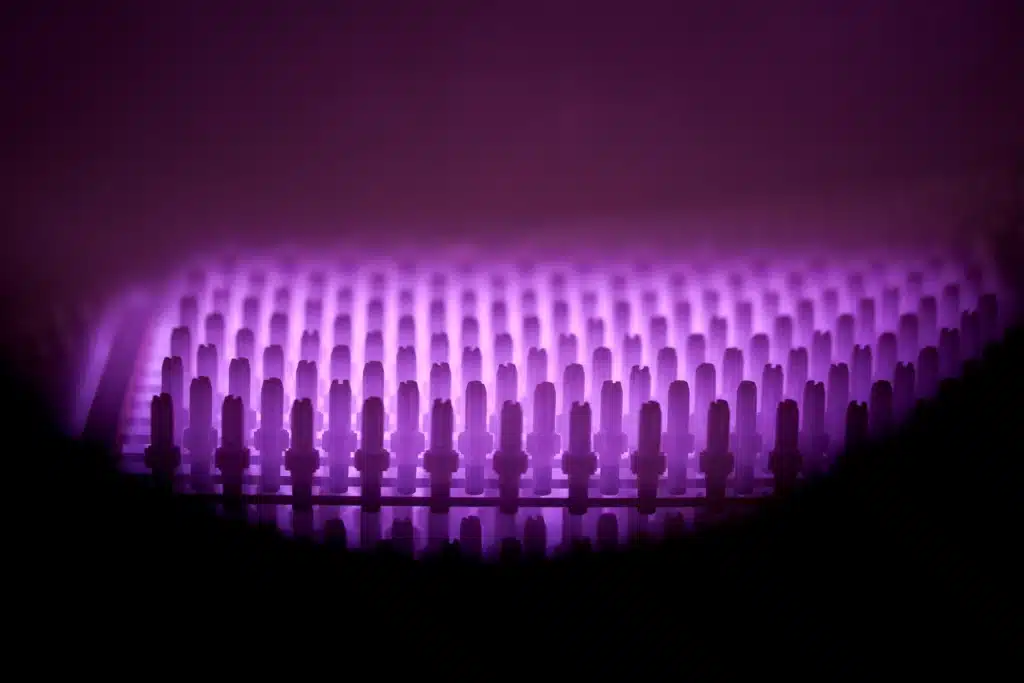

The ion nitriding process

Ion nitriding offers unrivalled advantages in terms of hardness and strength, making treated components ideal for the most demanding applications. To find out more about this revolutionary treatment, download our brochure on the subject!

The advantages of ion nitriding treatment

Ion nitriding is distinguished by its ability to offer flexibility in managing treatment parameters, enabling the creation of nitrided layers specifically tailored to each application (for each of your parts). The process produces an extremely hard combination layer and an underlying diffusion layer to improve overall wear and fatigue resistance.

This method is ideal for treating various steel grades, including stainless steels. Plasma's advantage is that it can be used to treat certain areas locally, resulting in effective savings through metal capping.

Applications for this treatment

Ion nitriding is particularly suitable for parts requiring high mechanical properties and increased resistance to operational stress, such as cams, extrusion screws and tooling. Thanks to its high precision, this treatment is used in sectors such asaerospace andautomotive, where reliability and performance are crucial. It is a preferred choice for finished parts or those requiring minimal finishing after treatment.

Further information

Ion nitriding offers unrivalled advantages in terms of hardness and strength, making treated components ideal for the most demanding applications. To find out more about this revolutionary treatment, download our brochure on the subject!

Other resources for your project:

- The different types of nitriding

- The benefits of plasma nitriding

- Sulfonitrocarburizing, a sulfur-doped ionic nitrocarburizing process