Decarburization is one of the everyday challenges associated with the heat treatment of metals. It is a chemical reaction that takes place when steel parts are heated in the presence of oxygen. The carbon present in the treated materials evaporates, causing them to lose their natural resistance to wear and tear, and increasing the risk of breakage through cracking. To avoid the problems associated with decarburization, there are two main methods: treatment in a controlled atmosphere or vacuum, and reworking by removing the decarburized layer, to upgrade damaged parts.

Why avoid decarburization?

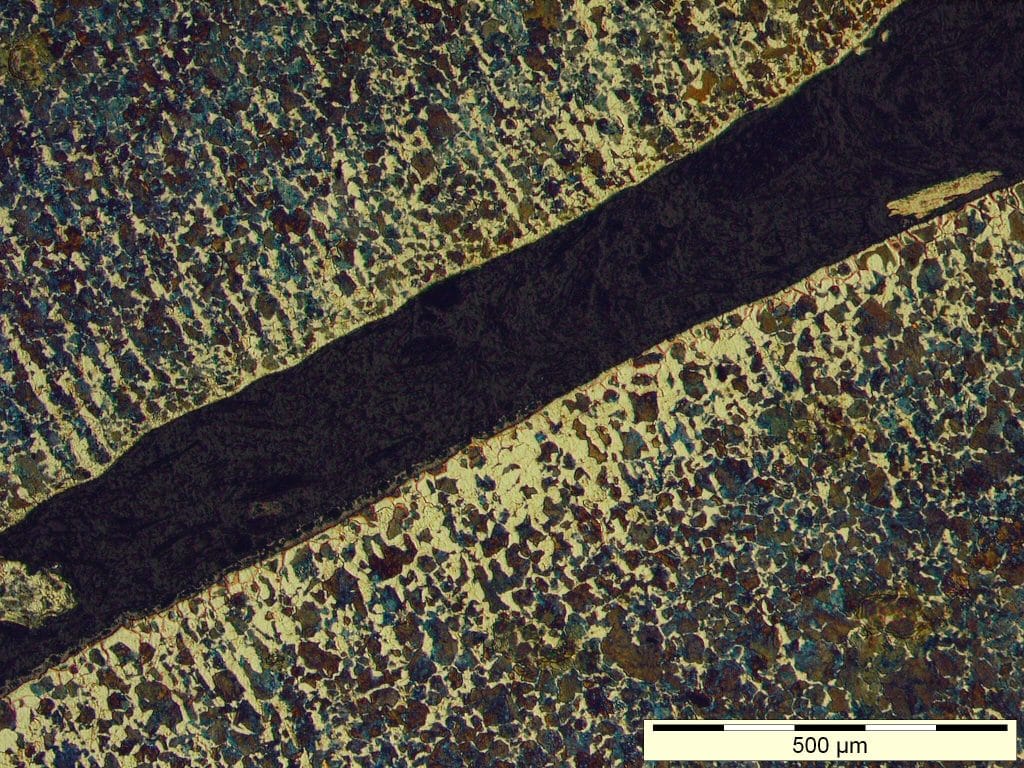

The phenomenon of decarburization can be observed on steel parts. As the name suggests, it affects the carbon content on the surface of steel parts following a heating operation. Decarburization is an undesirable chemical reaction that reduces the carbon content, thus weakening the strength of the parts.

In practice, this phenomenon occurs when steel is heated in the presence of oxygen. The alloy, made up of Fe and C atoms, reacts with O2 to create CO2. The carbon in the steel used to make the parts evaporates to form this gas, reducing the carbon concentration on the surface of the part. The hardness of steel depends above all on its carbon content. Each time they are heated in an oxygen-containing atmosphere, parts are decarburized, creating a real risk of breakage.

In the long term, the consequences of severe decarburization can be manifold: surface cracks propagating to the core of the part and causing it to break, and reduced surface hardness and wear resistance. It therefore seems essential to prevent decarburization.

Various solutions to prevent this phenomenon

The first thing to do to avoid decarburization seems obvious: prevent the presence of oxygen in the atmosphere of the heat treatment applied to steel parts. Several options are then available to professionals, who can also choose to carry out re-machining following essential treatments.

Changing the treatment atmosphere

The first solution to prevent decarburization is to ensure the absence of oxygen when heating the steel. Several controlled atmosphere heat treatment controlled atmosphere offer this possibility.

First of all neutral atmosphere treatmentswhich consists of diffusing nitrogen or argon, takes place in a totally oxygen-free environment. This method also logically reduces the risk of part oxidation, and is widely used for annealing, quenching or stabilization operations. In some cases, vacuum heating is also possible.

Carbon-based reactive controlled atmosphere treatments are also available. This technique consists in diffusing carbon during the operation, in the same concentration as that which is likely to evaporate and be transformed into CO2. For example, if the parts placed in the furnace contain 0.4% carbon, the atmosphere inside is charged with 0.4% of this chemical element, so as not to disturb the composition of the steel. This solution was specifically developed to avoid decarburization, and works thanks to sensors that adapt the carbon concentration in the treatment atmosphere.

Machining parts

Another method of avoiding decarburization is to remove the decarburized zone with a machining operation. This is known as re-machining : the decarburized zones are removed. Most of the time, however, it is still necessary to rework the whole part to avoid discrepancies, which can be quite costly and time-consuming.

Decarburization is a natural phenomenon that occurs when steel is heated in the presence of oxygen. This causes a chemical reaction in which the carbon evaporates, greatly reducing the material's resistance to wear and increasing the risk of breakage. There are two main ways of avoiding decarburization: treatment in a controlled atmosphere and reworking. In the first case, the treatment furnaces diffuse a neutral or reactive atmosphere, charged with carbon, so that the treated parts retain their carbon content. In the second, decarburized components are re-machined to retain their initial properties after treatment. In many cases, the former is the most suitable and economical solution.