business sectors concerned

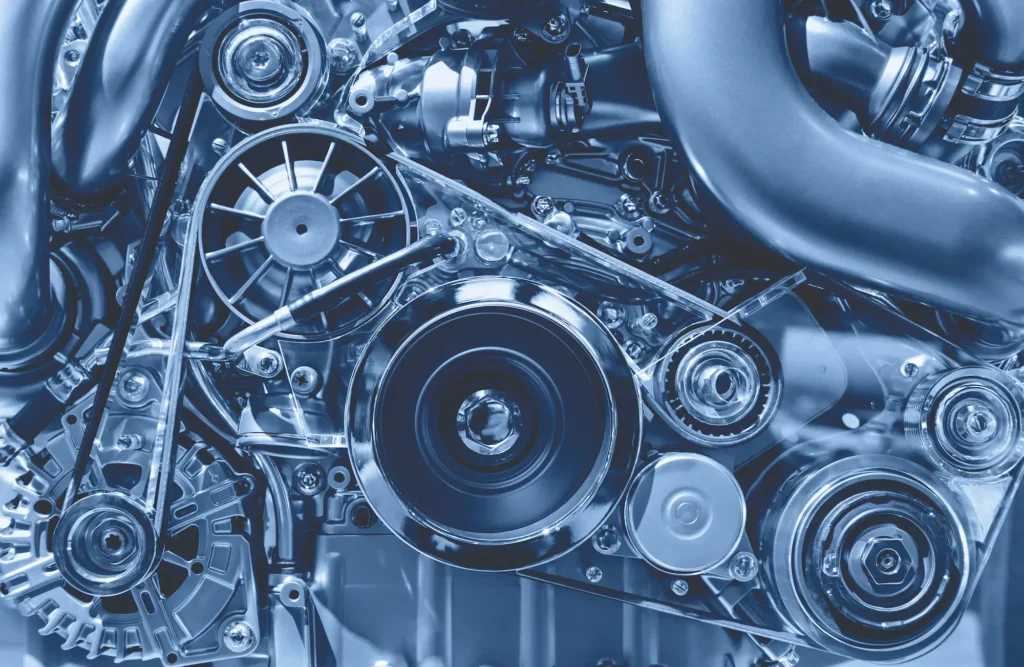

The versatility of these coatings enables them to meet the needs of a wide range of sectors.

Our various documentations

Our FAQs

Vacuum deposition is a surface treatment used to deposit a material or alloy on a mechanical part.

The use of vacuum technology ensures a perfectly clean, non-polluting process.

It is not subject to REACH legislation.

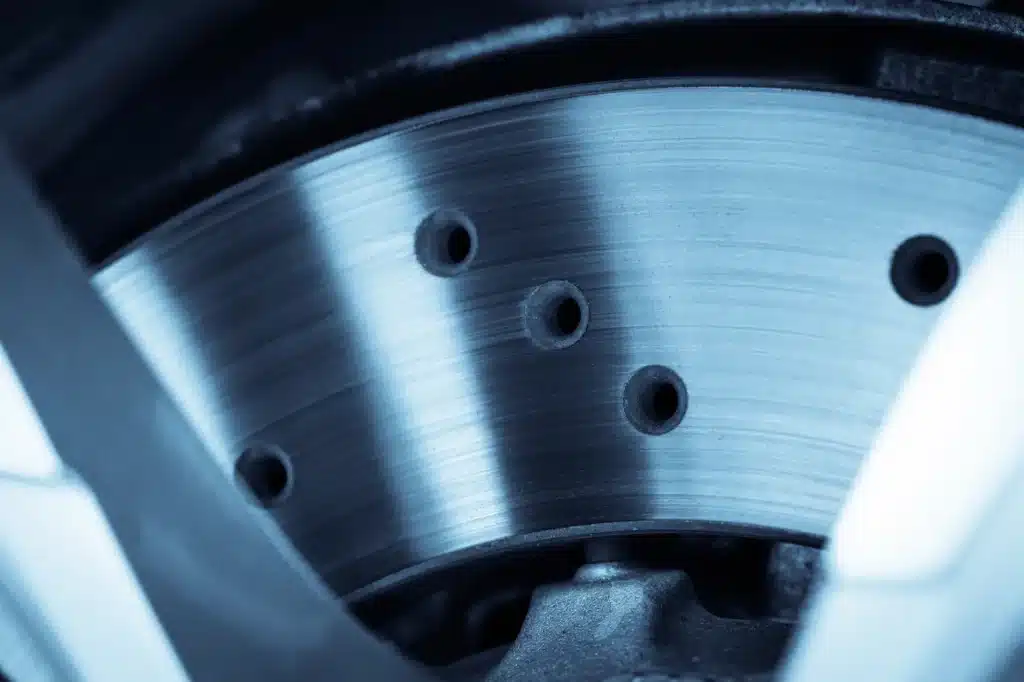

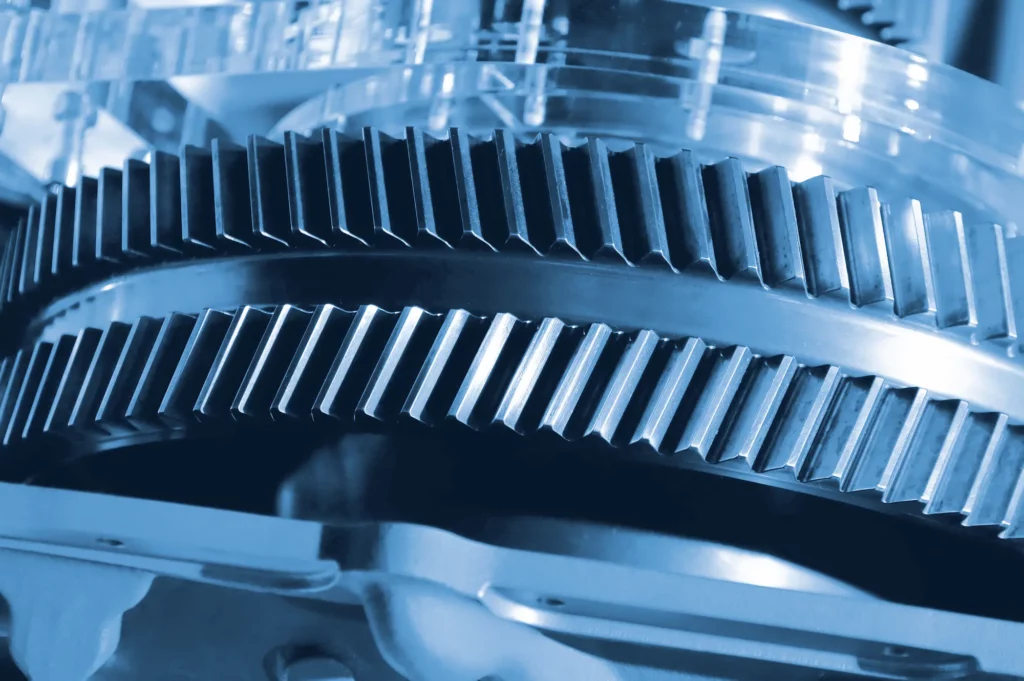

This process greatly increases resistance to wear, abrasion, friction and corrosion. As a result, component life is greatly extended.

Standard thicknesses are of the order of 3µm and deposition is carried out on finished parts.

PVD is physical vapor deposition. The element to be deposited is obtained by evaporation or sputtering via a physical process. PACVD is plasma-assisted chemical vapor deposition. The element to be deposited is obtained from chemical reactions. Plasma enables this chemical reaction to take place at lower temperatures.

Vacuum deposits are classified into several categories: anti-wear, friction, decorative and biocompatibility. The applications are therefore very varied: automotive components, aerospace, tooling, cutting tools, medical devices, decorative parts...

The deposition method depends above all on the nature of the coating to be deposited and the substrate.

If the substrate cannot be heated to high temperature, the deposition must be carried out using low-temperature technology.

If the coating to be deposited consists of a solid element (metal or graphite target), a physical process such as PVD is used. If the coating consists of a gas or liquid, a chemical process such as CVD or PACVD is used.

Incorporate carbon below the surface of the steel part to improve fatigue and wear resistance on the surface, while maintaining good core mechanical properties.