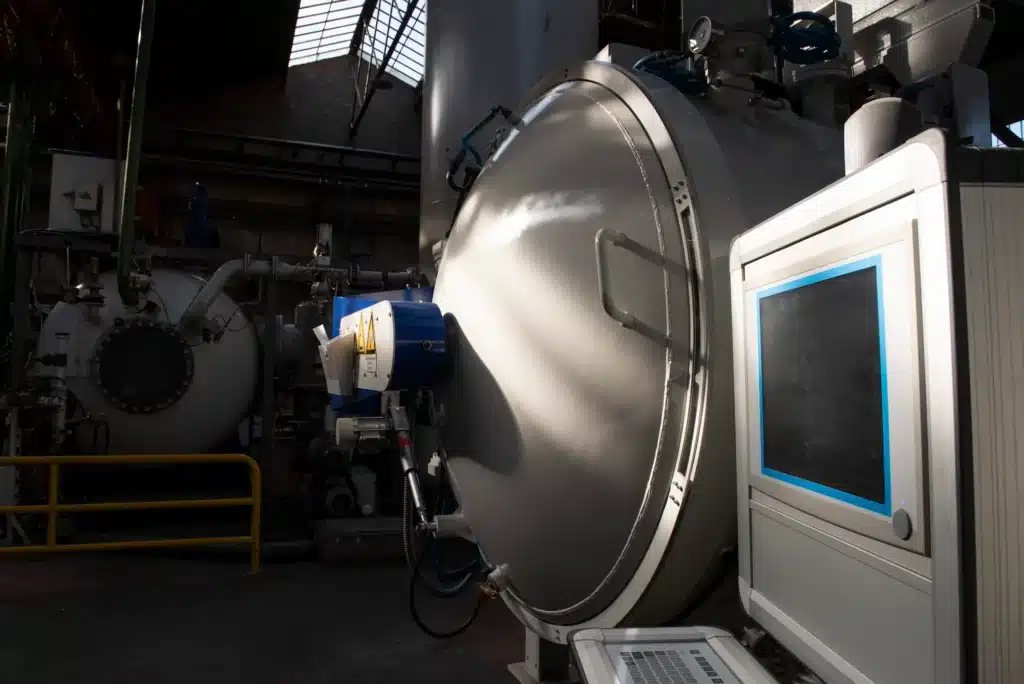

The advanced 20-bar gas quenching process

Discover our advanced 20-bar gas quenching technology, a state-of-the-art process designed to achieve optimum hardness with minimum deformation. This heat treatment under vacuum conditions ensures unrivalled cleanliness and precision in metal hardening, suitable for high-specification industrial applications.

Key benefits of gas quenching at 20 bar

The 20-bar gas quenching process offers significant advantages over other (traditional) quenching methods. Using a controlled vacuum environment and inert gases at high pressure, this technique prevents oxidation and decarburization, thus preserving the integrity of the metal surface. Precise control of austenitizing temperatures and rapid cooling rates, tailored to steels and component geometries, ensures uniform hardness and structural martensitic transformation. This method not only improves the wear resistance of treated parts, but also significantly reduces cleaning and post-treatment costs, thanks to the elimination of oil quenching residues.

Possible industrial applications

Ideal for components requiring high cleanliness and precise mechanical properties, gas quenching at 20 bar is widely used in industries such asaerospace,automotive and precisionengineering. The treatment is particularly effective for parts such as gears, bearings and surgical tools, where exact tolerances and mechanical strength are crucial.

The fully automated system guarantees consistent results for every batch, with each cycle meticulously monitored and adjusted for temperature, pressure and gas composition, offering unrivalled reproducibility and reliability.

Further information

Gas quenching technology at 20 bar illustrates precision in heat treatment, offering superior metallurgical results with reduced environmental impact. Find out in our guide how this advanced process can be integrated into your production flow to improve the performance of your components!

Other resources to help you go further:

- Innovations in steel quenching

- Atmospheric quenching or vacuum quenching, which to choose?

- Choosing the right heat treatment process